DAHS Replacement

A DAHS replacement can span from a simple update of the computer software to ensure compliance with current regulations and user standards to a full replacement of the computer and all relevant software. Changes to the DAHS must be tested for compatibility to all associated components of the CEMS. Any issues with communication must be resolved, including additional parts and software updates and replacements.

DAHS replacement begins with a computer (or server) upgrade and installation of the current or the latest compatible software. Depending on the nature of the project and the age of the DAHS related components in the unit itself, a PLC, OIT replacement, and/or RealView upgrade may also be recommended.

Prior to DAHS replacement, CiSCO offers a remote or onsite full assessment of the unit by a project engineer. Recommendations and a proposal will be created to update the unit to meet the current applicable rules and regulations.

Two years of hourly, calibration and QA data stored in the current system is converted, if required, and is backed up so that it may be transferred to the new system. CiSCO’s CeDAR DAHS software is installed onto the new equipment. If the unit falls under regulation 40CFR75, CiSCO’s EDR software, breeze75x, will also be added to the new system. ViewNode software allows remote access to the DAHS with minimal restrictions. Once installation of the new DAHS is completed, the stored data from the outdated system will be transferred to the new system and the DAHS synced to the CEMS unit.

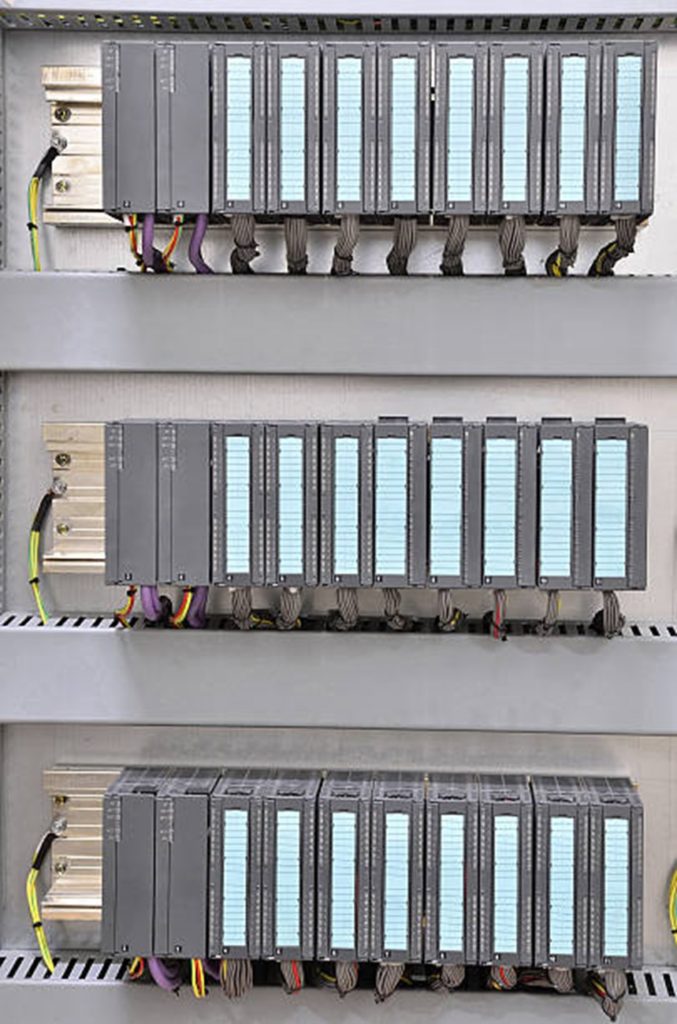

Age and compatibility are the two most crucial factors when replacing the PLC. If the PLC hardware is older than 10 years, a full replacement is generally required. This includes the processor, I/O, and CiSCO’s standard programming code for the PLC. This code is customized for each project so that it is site and unit specific. Alternatively, a newer system may simply require new or altered software to ensure compatibility with the new DAHS, leaving most or all the hardware as is.

OIT replacements or RealView upgrades are generally required with hardware replacement. The OI T panel or RealView computer allows for the end user to easily make adjustments directly to the PLC.

Included with the purchase of a DAHS Replacement are two quarters of EDR preparation and assistance (40CFR75 sites only). The client is also provided with any relevant documentation including the DAHS Spec, the CeDAR Manual, and documentation for the Customer Factory Acceptance Test.* The final product will be quality assured prior to the aforementioned test, delivery, and installation at the site.

The above description is not all inclusive. Projects may be customized to suit the needs of the plant to ensure that all units are compliant with all applicable regulations.

*Please note, due to the ongoing COVID-19 pandemic, the Customer Factory Acceptance Test is available virtually or in-person at the CiSCO site. Customers are required to follow all safety measures provided by CiSCO at all times while on CiSCO premises.