Frequently Asked Questions

Analyzers

No, but we service several leading brands including Siemens, Rosemount, Teledyne Advanced Pollution Instrumentation, Thermo Scientific, and Brand-Gauss.

No, we provide analyzers by customer request. We can recommend the best analyzer(s) depending on the customer’s requirements and the final application of the analyzer

We regularly service and carry parts for many of the top brands of analyzers including Rosemount, Teledyne, Thermo Fisher Scientific, and Siemens. Our Analyzer Technicians will attempt to service analyzers outside of these brands, but resolution is not guaranteed. If the issue cannot be resolved in-house, the analyzer will be returned or shipped to the manufacturer for repairs and maintenance.

Service time is dependent on the severity of the repairs and parts needed. Turnaround time for simple repairs that do not require parts or require parts that we carry can be as little as 24 hours. Intensive repairs that require parts that need to be ordered can take more than 1.5 weeks. The average service time for typical repairs, from arrival to departure of our facility, is generally 3-4 days. Our analyzer technicians perform extensive bench testing after all service and repairs to ensure the reported issue has been corrected.

We do have a small inventory of miscellaneous used analyzers in stock. These analyzers are available for sale, set up and configuration for our customers. Please contact CiSCO at info@ciscocems.com for a list of current items as the inventory is constantly changing.

Rosemount 951C is no longer supported by the manufacturer. We do carry a limited number of spare parts for these analyzers to maintain proper operation. Unfortunately, once our inventory is exhausted, we will no longer be able to service Rosemount analyzers.

Thermo Fisher has stopped the manufacture of their i-series analyzers and has released their iQ-series. Currently, we are still able to order parts, offer support, and provide service for analyzers from the i-series.

Analyzer training classes are scheduled by request either inhouse, at your facility, or online.

Data Acquisition Handling System (DAHS)

40 CFR 75 requires reporting in standard time year-round and therefore does not allow you to change to daylight saving time. If your computer adjusts for daylight saving time you may have an hour of missing data and an hour of overwritten data.

PCs in the shelters are considered optional. If you would like to have a ViewNode or RealView set up in the shelter, please contact CiSCO’s software department for options and pricing at (303) 790-1000.

On-Time is the actual time the unit ran, counted from flame on to flame off and is reported in tenths of an hour. Op Hours are the number of clock hours in which the unit operated and are integer values and not portions of an hour. Op Hours are displayed on the Exceedance and Downtime reports; On-Time is displayed on the daily and monthly reports.

The Database Editor does not communicate with the PLCs. Any setting that is written to the PLC must be changed through the Data Monitor, not the Database Editor.

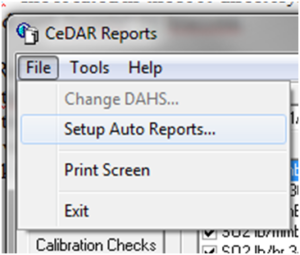

1. In the CeDAR Report Generator, open the File menu and choose “Setup Auto Reports…”.

2. On the left-hand side of the screen choose the type of report you would like to have auto reported. In this example we will choose a daily report.

3. Select the ![]() button to setup the auto report.

button to setup the auto report.

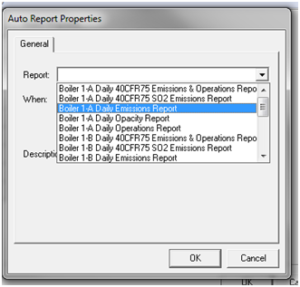

4. In the “Report:” dropdown menu select the report you would like to add.

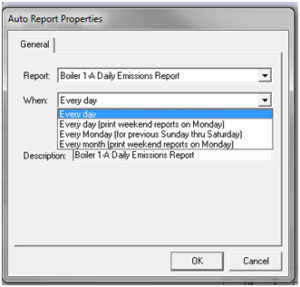

5. Choose when you would like to print.

6. Modify the report description as you desire and select OK.

7. At the top of the screen, you can select additional destinations where the auto report will print such as the default printer, named printer, email (PDF), or email (CSV).

![]()

8. If you have any questions or need assistance, feel free to call CiSCO’s Software Support at (303) 790-1000.

Sometimes the startup or shutdown signal from the PLC has a delay or the conditions to determine the turbine status weren’t met at that time. To fix this problem open the Database Editor.

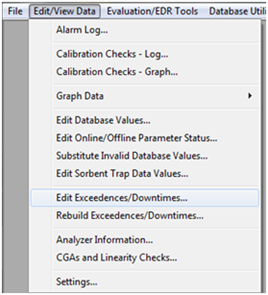

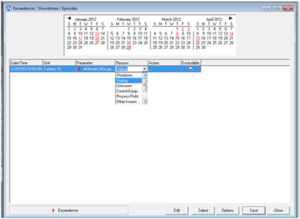

- Select the “Edit/View Data” menu. Select the “Edit Exceedences/Downtimes…” option.

- Choose the date in the calendars displayed at the top of the screen with the exceedance that was supposed to be flagged as startup or shutdown.

- Mark the check box on the right to indicate the parameter is excludable.

- Select the reason box. Click the dropdown menu arrow and choose the appropriate reason from the list.

- Choose Save at the bottom of the window and close the Database Editor.

If you have any questions, please feel free to contact CiSCO’s Software Support at (303) 790-1000.

CAL Calibration

CEMS Continuous Emission Monitoring System

CERMS Continuous Emission Rate Monitoring System

CGA Cylinder Gas Audit

CGT Cylinder Gas Test

DAHS Data Acquisition Handling System

DARS Data Acquisition Reporting System

DAS Data Acquisition System

EDR Electronic Data Report

HMI Human Machine Interface (see OIT)

HSL Heated Sample Line

LIN Linearity

OIT Operator Interface Terminal (see HMI)

PB Power Box

PGVP Protocol Gas Verification Program

PLC Programmable Logic Controller

PPM Parts per Million

PS Power Strip

RATA Relative Accuracy Test Audit

SCR Selective Catalytic Reduction

TB Terminal Barrier

TS Terminal Strip

UPS Uninterruptable Power Supply

| Daily Cal Cylinders | |

| Days until expiration | Alarm |

| >60 | None |

| 60 | Warning |

| 4-59 | Warning, Tuesdays Only |

| 2-3 | Warning |

| 0-1 | Serious |

| Expired 1 day | Serious |

| Expired >1 days | None |

| CGA/Linearity Cylinders | |

| Days until expiration | Alarm |

| >60 | None |

| 60 | Warning |

| 31-59 | None |

| 30 | Warning |

| 1-29 | None |

| 0 | Warning |

| Expired | None |

Most CeDAR sites use the hourly average for the measured values instead of calculating the average using the minute data. For example, the hourly average for the NOx at 15% O2, CeDAR would use the hourly average for the O2 percentage and the hourly average for the NOx ppm instead of using the minute averages for the NOx at 15% O2 to calculate the average. All calculations reported in your quarterly 40 CFR 75 EDR follow this methodology.

State and/or local regulatory agencies may require different types of averages for reporting purposes. For example, Pennsylvania Department of Environmental Protection (PADEP) requires the minute values to be used for averages for values at 15% O2, lb/MMBtu, and lb/hr.

Electronic Data Reports (EDRs) / ECMPS Client Tool

- Test results

- 40 CFR 75 megawatts during the test (found in the audit section of the CEDAR Report Generator)

- Protocol Gas Verification Program (PGVP) data for all three levels of NOx and O2 gases including:

-

- Vendor ID

- Cylinder ID

- Gas type (e.g., CO = EPA protocol gas bi-blend consisting of O2, CO, and a balance gas)

- Expiration date

- Gas Level (i.e., low, mid, high)

- Air Emission Testing Board (AETB) information including:

-

- First and last name of the certified RATA team tester

- AETB name (name of the company that performed the RATA)

- AETB phone number

- AETB email address

- Exam date of certified RATA team tester

- Provider name (company that tested and certified the RATA team tester)

- Provider email address

No, only when entering linearity and upscale span gases.

The data is invalid until a linearity is rerun with a non-expired and certified gas cylinder. However, if there is a minimum of 100 psi in the cylinder, you can have it reanalyzed and recertified by the gas vendor.

Have the test team supply their AETB certificates before sending them a PO.

A 40 CFR 75 RATA needs to run at normal or second normal load as shown in the monitoring plan. Make sure you are looking at “40 CFR 75 MW” to determine the load. The High Load is 60‑100% of the range, Mid is 30‑60% and Low is 0‑30%. So, if the low (minimum) MW value is 20 and the high is 120, the High load would be 80-120 MW, Mid 50-80 MW, and the Low 20-50 MW. In contrast, a 40 CFR 60 RATA must be at a MW level that is at least 50% of your normal operating load.

Only if it will allow for the proper load range during the RATA. Please note that in rare cases the permit qualifies duct burner operations as part of normal operations for a 40 CFR 60 RATA.

Use the Resubmit Request Form at http://ecmps.camdsupport.com/help_resubmit_form.shtml to request permission to make changes to your EDR.

Yes, but there is not a specific load requirement.

40 CFR 60, Appendix F does not require the plant to be online, however it is good practice for the stack conditions during a QA test to be similar to those during emission sampling.

40 CFR 60, Appendix A, Method 7E indicates that calibration must be based on the NO gas value. What are the NO/NOX/NO2 requirements for 40 CFR 75 regarding the certified gas values used for calibration, linearity, and the RATA reference analyzer?

Most protocol gas bottles are only certified for the concentration of NO. However, vendors are providing calibration gases that do certify both NO and NOX concentrations. 40 CFR Part 75 Policy Manual Question 9.34 provides options indicating which certified values are appropriate. If the analyzer measures total NOX, you may use either the certified NO concentration or the certified NOX concentration. Otherwise, if the analyzer only measures NO you may only use the certified NO concentration. In addition, an NO2 EPA Protocol Gas must also be used when calibrating a reference analyzer that measures NO and NO2 separately without a converter. If you have any further questions, contact CiSCO’s environmental department at (303) 790-1000.

What is the 4-hour rolling emission limit for a 200 MW CTG having a maximum heat input capacity of 850 MMBtu/hr that includes startup and shut down hours for 40 CFR 60 Subpart KKKK?

Since subpart KKKK is silent on periods of startup, shutdown, and malfunction the general provisions exclude these periods from being considered a violation of the numerical emissions standard. Any 4-hour period that contains either a startup, shutdown, or malfunction would be exempt from being considered a violation of the numerical standard. However, you would still have to report excess emissions for these periods and explain the 4-hour period including SSM and why it is not a violation of the numerical standard.

Because the turbine output is greater than 30 MW, then during startup/shutdown (less than 75% load) the applicable hourly standard would be 96 ppm. If the output was under 30 MW, then it would be 150 ppm. The “north of the arctic circle” rows at the end of Table 1 would apply if any of the listed conditions apply. The actual 4-hour average that they would report excess emissions against is a blended average. For example:

| Hour 1: | Startup (less than 75% of load at some point during the hour) – limit is 96 ppm (could be 150 ppm depending on the output) |

| Hour 2: | Operating at 60% load – limit is 96 ppm |

| Hour 3: | Operating above 75% load for the entire hour – limit is 25 ppm (since maximum heat input is less than 850 MMBtu/hr |

| Hour 4: | Shutdown – limit is 96 ppm for a 4-hour standard. (96 + 96 + 25 + 96)/4 = 78 ppm @15% O2 |

A 3-Load RATA should be performed at least once every five years. In general, a 2-load RATA should be performed annually. If a unit operates within one load at least 85% of the time a single load RATA is acceptable.

Yes, the new RATA should represent an unbiased system.

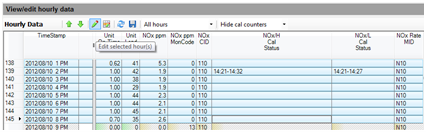

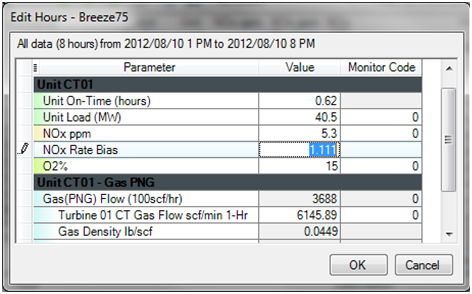

- In breeze75x, highlight the data where the bias factor is incorrect (CTRL + Shift) and select the edit button

.

.

- Change the bias factor to the correct value, choose OK.

- Finish by selecting the save

button and refresh the data

button and refresh the data  before generating the report to re-import into the Client Tool.

before generating the report to re-import into the Client Tool.

Depending on the age and model of your PLC and panel it may not be possible to enter this information at these locations. However, newer PLCs and panels do support this feature. Since PLCs and panels are unique to sites, there is not an easy way to update existing panels and PLC logic without updating them individually. A change like this would likely require a PLC upgrade since some systems do not have the space or capability to handle alpha numeric fields.

Yes, both CeDAR and breez75x will allow you to enter both capital and lower case letters for the vendor ID. The logic is that at some point, the EPA may add vendor ID’s with lower case letters. breez75x will not convert the lower case letter to a capital letter when you create the EDR. The Client Tool will check vendor ID’s in the EDR against the vendor ID list, so make sure you enter a capital letter if the letter is capitalized on the vendor ID list or the gas certification sheet.

If you have a RealView (which is the Windows-based version of the OIT), CiSCO can enable that feature if it has not been enabled at your site. Contact CiSCO’s software department for more information at (303) 790-1000.

Zero calibrations gases and gases that are Part 60 only do not fall under PGVP and therefore do not get reported or have gas type codes. There are place holders in the settings window in the Data Monitor and the Database Editor for you to track this information.

Quarterly CGA’s do not fall under PGVP because they are a Part 60 requirement, but linearities do require this information because they are a Part 75 requirement. There are place holders in the CGA/Linearity window in the Database Editor for CGA’s in case you would like to track this information. However, you are not required to electronically report this information and there are not any gas type codes for these gases. Newer panels and RealViews also allow you to enter the information for the CGA bottles.

Yes. Enter the same cylinder number in the appropriate place for each unit. However, you cannot use the same cylinder number for different types of gases.

When you recertify a gas, you send it back to the gas company. Once they recertify it, they send it back with a new expiration date, but the cylinder number will stay the same.

Only if the NO2 component is certified. Since NO2 is not very stable, it usually isn’t certified. In that case the code would be NO plus the balance gas. For example, use the code NO,BALN when nitrogen is the balance gas. Check your gas certification sheets or call your gas vendor to see if the NO2 component is certified.

If the NO2 component is not certified then the gas type code would be NO,CO,BALN.

If this gas is used for Part 60 calibrations, no gas type code is required. Leave this field blank.

Environmental

It depends on the test and the applicable regulation which are outlined in the table below. Note that state or local air district regulations could override Part 60 requirements.

40 CFR 60

| Daily Calibrations | May be performed offline.1 |

| Calibration Drift Test | Must be performed while the facility is operating normally. (40 CFR 60 Appendix B, Performance Specification 2, 8.3.1) |

| Relative Accuracy Test Audit (RATA) | Must be performed while the facility is operating at more than 50% of the normal load. (40 CFR 60 Appendix B, Performance Specification, 8.4.1) |

| Cylinder Gas Audit (CGA) | May be performed offline.1 |

| Response Time Test | Not required to be operating.1 It is CiSCO’s recommendation that this test is performed online since it is part of the initial certification, which is conducted online. |

40 CFR 75

| Daily Calibrations | Must be performed while the unit is in operation at normal, stable conditions (i.e., online). Offline calibrations may be used on a limited basis provided that the unit has performed an “offline calibration demonstration” as part of the initial certification testing or quarterly QA testing.2 (40 CFR 75 Appendix B, 2.1.1) |

| 7 Day Calibration Error Test | The unit must be combusting fuel, but not necessarily generating electricity. (40 CFR 75 Appendix A, 6.3.1) |

| Linearity Test | The unit must be combusting fuel, but not necessarily generating electricity. (40 CFR 75 Appendix A, 6.2) |

| Relative Accuracy Test Audit (RATA) | The unit must be combusting fuel and operating at a normal load. (40 CFR 75 Appendix A, 6.5.1(a)) |

| Cycle Time Test | Must be performed while the unit is operating. (40 CFR 75 Appendix A 6.4) |

The limit is determined by taking a blended average. See the example below for a new gas turbine rated at greater than 30 MW with a maximum heat input less than 850 MMBtu/hr.

| Hour 1 | Startup (less than 75% of the load at any point during the hour) – the limit is 96 ppm | |

| Hour 2 | Operating at 60% of the load – the limit is 96 ppm | |

| Hour 3 | Operating above 75% of the load for the entire hour – the limit is 25 ppm | |

| Hour 4 | Shutdown – the limit is 96 ppm | |

| 4-Hour Standard | (96+ 96+25+96)/4 = 78 ppm@ O2 | |

Please note that the CEMS data does not have to be continuous and must be collected backward regardless of the facility’s last operation.1

No. This does not qualify as a recertification event in the Part 75 Emissions Monitoring Technical Q&A (formerly referred to as the Policy Manual).1

CiSCO was informed by the US EPA that 40 CFR 60 compliance, in most cases, has been delegated to the state or local air agencies. CiSCO is in the process of completing a comprehensive list of each state’s protocol for these events. If this information is not in your current CiSCO CEMS Quality Assurance Manual, please contact the environmental department at (303) 790-1000.

- The calibration does not meet 40 CFR 75 criteria. Facilities that fall under 40 CFR 75 should confirm that the company performing the fuel flowmeter calibrations knows the requirements of 40 CFR 75, Appendix D, Sections 2.1.5 and 2.1.6. Their documents should confirm this information.

- Improper use of popular Coriolis fuel meters. Currently, Coriolis fuel flowmeters can only be used by petition unless they have been calibrated using the requirements of 40 CFR 75, Appendix D, Sections 2.1.5.2.

- Mistiming of calibrations. It is important to remember that the compliance period for fuel systems that include both combustion turbine (CT) and duct burner (DB) fuel flowmeters start with the unit that was calibrated first. For example, if the CT and DB meters were calibrated 2021Q4 and 2022Q2 respectively, the next calibration will be based on the CT meter. In addition, facilities that use the transmission/transducer calibrations provided in 40 CFR 75, Appendix D, Sections 2.1.6. need to confirm that a primary element inspection (PEI) has been completed in the same or adjacent quarter or use the fuel flow-to-load option provided in 40 CFR 75, Appendix D, Sections 2.1.7.

Currently, the Part 75 Emissions Monitoring Technical Q&A defines a like-kind analyzer as one that uses the same method of sample collection (i.e., dilution-extractive, dry extractive, or in‑situ) and analysis (e.g., pulsed fluorescence, UV fluorescence, or chemiluminescence) as the analyzer that it replaced. While the Part 75 definition allows for the use of analyzers made by different manufacturers, certain state agencies have the additional requirement that the replacement analyzer must have the same manufacturer and model number.

- EPA correspondence confirming this procedure is on file.

- Note that the first calibration for initial certification or recertification must be online.

Programmable Logic Controller (PLC)

& Human machine Interface (HMI)

No. The current Real Time screens are a set size. Giant Numbers, Bar Graphs, and Trends are all resizable.

On the HMI or RealView, set the Backflush interval to Zero.

Often the touch screen displays a calibration-corrected value unless you are in Out-of-Service mode. While in Out-of-Service mode, the analyzer and the HMI should show the same number.

If the numbers displayed on the screens are different while in Out-of-Service mode, the analyzer will need to be tested to determine if its output is correct. CiSCO CEMS units provide test jacks from each analyzer to measure its voltage. Use the known voltage value and the range of the instrument to calculate the output. Compare it to the displayed value to determine if it is correct.

If you need assistance, please contact CiSCO at (303) 790-1000.

The analyzer is checked against a calibration gas each day. The calibration gases flow through the same path as the source gases to ensure a complete sampling system check. If the analyzer reads the calibration gas correctly, the instrument should give an accurate indication of the process emissions.

An oxygen analyzer is the best diagnostic tool to determine leaks between the probe and the analyzer. If one is included in your system, flow zero gas to the oxygen analyzer and monitor the displayed value after it is stable. Continue to flow the gas and turn the probe/cabinet valve to the cabinet position and watch for a different displayed value. If the difference between the displayed values is greater than 0.2% there is a vacuum leak in the system. If the difference between the two values is less than 0.2% the system is leak free.

Shelters

None, but there are shipping constraints. Shelters must not exceed 12 feet in width unless accompanied by both a lead and trail car.

Yes, we frequently use redundant HVAC units.

Our shelters exceed the size for a NEMA rating, but our cabinets are NEMA rated.

We use milled steel. The gauge of steel that is used in a project is dependent on the requirements of the end user. With proper maintenance, a CiSCO shelter will last over 30 years. Comparable wood shelters have a much shorter life expectancy.

We use Kynar painted steel panels that are either 20, 22, or 24 gauge. The panels carry a 30 year warranty.

Yes. Class 1 Division 2 shelters are standard for liquid natural gas and oil refineries. We have a loyal customer base in both these markets.

Yes. We can customize your project to fit your needs including the addition of other furnishings like racks and desks.

R19 is our standard, but we can increase the R value by modifying the building structure.

Yes. We can mount them to exterior walls or set them on a concrete slab inside a lateral-running door to allow protection and easy, roll-in access.

We have built shelters designed to hold as many as six CEMS units. However, these units tend to have complications with the heated sample length, which requires more power in the shelter. It is recommended to limit the number of units in a shelter to 2 to promote better power consumption by reducing the heated sample lengths.

Lead time is dependent on the current open projects in our Production warehouse, drawing approval and available materials. If these conditions for your project are favorable, we can meet a 16-20 week turnaround. Due to current market conditions and supply chain complications, we cannot guarantee any deadlines at this time.

In our 30+ year history, we have not needed to replace one of our shelters for any reason other than accidents or natural disasters. We would estimate that a CiSCO shelter should last at least 30 years with proper maintenance.

Snow loads on shelters are taken into consideration and adjusted to endure the end user’s climactic conditions. We also send our drawings out for professional structural engineering approval and stamp.